Differences Between and

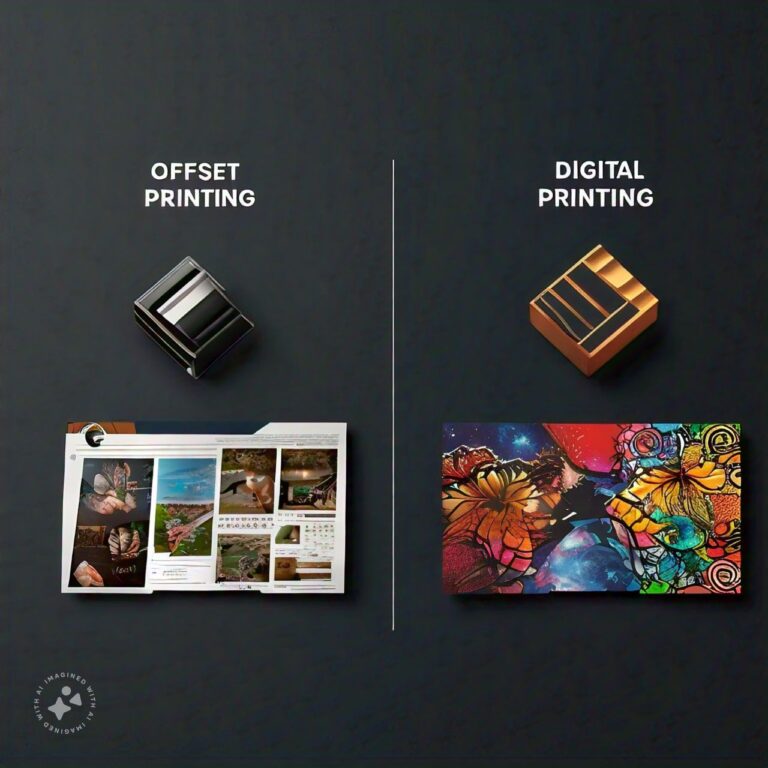

In the world of printing, two of the most common methods used are offset printing and digital printing. Both printing technologies offer unique advantages and are suited for different types of projects. Offset printing, a more traditional method, is renowned for its high quality, efficiency in large print runs, and ability to print on various materials. Digital printing, on the other hand, is a more modern approach, known for its versatility, speed, and cost-effectiveness for shorter print runs.

Understanding the differences between offset and digital printing can help individuals and businesses make more informed decisions when choosing the most appropriate method for their printing needs.

Overview

What is Offset Printing?

Offset printing, also known as offset lithography, is a traditional printing technique that involves transferring an inked image from a metal plate to a rubber blanket, and then onto the printing surface, typically paper. The term "offset" refers to the fact that the ink is not applied directly to the paper but is transferred or "offset" from one surface to another.

Offset printing is widely used for high-volume commercial print jobs, such as magazines, newspapers, brochures, and packaging. It is valued for its ability to produce high-quality, consistent prints with sharp images and precise color reproduction.

How Offset Printing Works

Offset printing is a mechanical process that involves several key steps:

-

Plate Creation: First, the image to be printed is etched onto a metal plate, typically made of aluminum. Each color in the image requires a separate plate. The plate contains the design and is mounted on a cylinder inside the printing press.

-

Ink Application: Ink is applied to the plate. The ink adheres to the image areas of the plate, while non-image areas are treated with a water-based solution that repels ink.

-

Rubber Blanket Transfer: The inked image is transferred from the plate to a rubber blanket that wraps around another cylinder. This rubber blanket then "offsets" the image onto the printing surface (usually paper).

-

Printing Process: The paper passes between the blanket cylinder and an impression cylinder, which applies pressure and transfers the ink from the blanket onto the paper. This process can be repeated multiple times for different colors (typically cyan, magenta, yellow, and black, or CMYK).

-

Drying and Finishing: Once printed, the paper passes through a drying unit to set the ink. Afterward, it may undergo various finishing processes such as trimming, folding, and binding.

Advantages of Offset Printing

-

High Image Quality: Offset printing delivers exceptional image quality, with sharp details, precise colors, and consistent results across large print runs.

-

Cost-Effective for Large Quantities: While the setup costs for offset printing can be high, the per-unit cost decreases significantly with larger print runs, making it an economical choice for bulk printing.

-

Color Accuracy: Offset printing offers excellent color reproduction, especially for complex designs that require precise color matching. It can print in both Pantone (spot colors) and CMYK (process colors).

-

Versatility in Materials: Offset printing can be used on a wide range of materials beyond paper, such as cardboard, plastic, metal, and fabric.

-

Long-Lasting Prints: Offset inks tend to be more durable and fade-resistant, making them suitable for prints that need to last, such as posters, books, and packaging.

Limitations of Offset Printing

-

High Setup Costs: Offset printing requires the creation of printing plates and extensive setup, which can be costly, particularly for smaller print runs.

-

Longer Turnaround Time: The setup and printing process for offset printing is more time-consuming compared to digital printing. It may take days or even weeks to complete a job.

-

Limited Customization: Since offset printing relies on plates, making changes or customizations to the design after the plates are created can be difficult and expensive.

-

Minimum Print Quantity: Offset printing is not cost-effective for small print runs due to the high setup costs.

Common Uses of Offset Printing

- Magazines: Offset printing is the preferred choice for producing high-quality, glossy magazines with vibrant colors and detailed images.

- Books: Most mass-market books are printed using offset technology due to its cost-efficiency for large quantities.

- Newspapers: Newspapers are printed using offset presses because they require high-volume production on a daily basis.

- Packaging: Offset printing is commonly used for high-end packaging and product labels that require excellent image quality.

Overview

What is Digital Printing?

Digital printing is a modern printing technique that transfers digital images directly from a computer to a variety of media surfaces without the need for printing plates. Unlike offset printing, which requires complex setup and plate creation, digital printing uses inkjet or laser technology to print the image directly onto the substrate.

Digital printing has gained popularity in recent years due to its speed, flexibility, and ability to accommodate short print runs. It is commonly used for print-on-demand services, personalized printing, and small to medium-sized commercial printing jobs.

How Digital Printing Works

Digital printing is a straightforward process that involves the following steps:

-

Digital File Preparation: The image or design to be printed is prepared in a digital format (such as a PDF or other digital file formats). This file is then sent directly to the digital printer.

-

Printing Process: Digital printers, such as inkjet or laser printers, use tiny droplets of ink or toner to reproduce the image onto the printing surface. Inkjet printers spray the ink onto the paper, while laser printers use static electricity to adhere toner to the paper.

-

No Need for Plates: Unlike offset printing, digital printing does not require the creation of plates, which eliminates the need for pre-press setup. This makes digital printing faster and more flexible.

-

Finishing: After printing, the paper may go through post-printing processes like trimming, binding, laminating, or other forms of finishing.

Advantages of Digital Printing

-

Quick Turnaround: Digital printing offers fast production times because it does not require the setup of plates or lengthy pre-press processes. It is ideal for projects with tight deadlines.

-

Cost-Effective for Short Runs: Digital printing is highly cost-effective for short print runs because it eliminates the setup costs associated with offset printing. Businesses can print small quantities on-demand without worrying about high overhead costs.

-

Personalization and Customization: Digital printing allows for variable data printing, meaning that each piece can be customized with different text, images, or graphics. This is useful for personalized marketing materials like direct mail, business cards, and promotional materials.

-

Print-On-Demand: Digital printing allows businesses to print only what they need, reducing waste and storage costs for excess inventory.

-

Environmentally Friendly: Digital printing produces less waste compared to offset printing because it eliminates the need for plates and chemicals used in plate-making. Additionally, it allows for just-in-time printing, which reduces excess inventory and waste.

Limitations of Digital Printing

-

Limited Color Matching: Digital printing may not offer the same level of color accuracy as offset printing, especially for Pantone or spot colors. While digital printers have improved, they may struggle with complex color matching for specific brand colors.

-

Higher Per-Unit Costs for Large Runs: While digital printing is cost-effective for small runs, the per-unit cost remains constant. This means that for large runs, digital printing can become more expensive compared to offset printing.

-

Lower Print Quality: Although digital printing technology has advanced, it may not match the print quality of offset printing, especially for very fine details, gradients, or highly vibrant colors.

-

Limited Material Choices: Digital printing is generally limited to certain types of paper and substrates, whereas offset printing can accommodate a broader range of materials.

Common Uses of Digital Printing

- Business Cards: Digital printing is ideal for printing small batches of business cards with personalized information or variable data.

- Direct Mail: Personalized direct mail campaigns benefit from digital printing because each piece can be customized with the recipient's name, address, and other personalized details.

- Posters and Banners: Digital printing is suitable for producing posters, banners, and large-format prints in small quantities with quick turnaround times.

- Brochures: Short-run marketing materials, such as brochures and flyers, are often printed digitally due to the lower setup costs and flexibility in design changes.

Differences Between and

-

Printing Method:

- Offset Printing: Uses plates to transfer ink to a rubber blanket, which then transfers the ink to the paper or substrate.

- Digital Printing: Transfers digital images directly onto the substrate using inkjet or laser technology, without the need for plates.

-

Cost:

- Offset Printing: Economical for large print runs due to lower per-unit costs, but high setup costs make it less cost-effective for short runs.

- Digital Printing: Cost-effective for short runs, as there are no setup costs, but the per-unit cost remains consistent, making it more expensive for large runs.

-

Turnaround Time:

- Offset Printing: Typically has a longer turnaround time due to plate creation, setup, and drying times.

- Digital Printing: Offers faster production times because there is no need for plates or drying, making it ideal for urgent jobs.

-

Customization:

- Offset Printing: Customization is more difficult and expensive due to the need for new plates for each variation.

- Digital Printing: Allows for easy customization and personalization, as each print can be unique without additional setup.

-

Color Matching:

- Offset Printing: Provides excellent color accuracy, especially for Pantone or spot colors.

- Digital Printing: Color accuracy may be lower, particularly when matching specific brand colors, although improvements in digital printing technology have narrowed the gap.

-

Print Quality:

- Offset Printing: Produces high-quality prints with sharp details and rich colors, making it the preferred choice for high-end marketing materials, magazines, and packaging.

- Digital Printing: While digital printing has improved significantly, it may not match the detail and color vibrancy of offset printing, especially for complex designs.

-

Print Run Size:

- Offset Printing: Best for large print runs, where the setup costs are spread across many units.

- Digital Printing: Ideal for small print runs or print-on-demand jobs, as there are no setup costs.

-

Environmental Impact:

- Offset Printing: Involves the use of plates, inks, and chemicals that can have an environmental impact, but advancements in eco-friendly inks and processes have reduced this.

- Digital Printing: Generally produces less waste and has a smaller environmental footprint due to its on-demand nature and elimination of plates and chemicals.

Conclusion

Both offset and digital printing have their distinct advantages and limitations, making them suitable for different types of projects. Offset printing excels in delivering high-quality, cost-effective results for large print runs and projects that require precise color matching and consistent quality. On the other hand, digital printing offers greater flexibility, faster turnaround times, and affordability for short print runs and personalized printing projects.

Ultimately, the choice between offset and digital printing depends on factors such as print quantity, budget, customization needs, quality requirements, and turnaround time. By understanding the strengths and limitations of each method, businesses and individuals can choose the right printing solution to meet their specific needs.

FAQs

Related Topics

- All

- Animals

- Diseases

- Health

- Money

- Politics

© 2024 OnYelp.com. All rights reserved. Terms and Conditions | Contact Us | About us